Hi All,

As promised in my last post, I am back with WMS feature in AX 2012 R3. This is very interesting and absolutely a new module that has been added to AX 2012 R3 whose purpose is basically to monitor and automate warehouse processes. WMS in AX is an Advanced distribution which provides complete real time and global view in the business efficiently.

Warehouse Management for Microsoft Dynamics AX is an integrated warehousing solution for advanced distribution and order fulfillment that adds to the current capabilities of Microsoft Dynamics AX to support distribution companies and logistics providers.

Overview of Features:

- You can configure inbound and outbound intelligent workflows.

- You can assign orders to clusters to pick from a single location, and configure profiles to control the validation and packing of items into shipping containers.

- You can create, implement, and release work by using batch-scheduled or manual processing of waves.

- You can set up cycle counting thresholds, create and schedule counting plans, and cycle count locations and items.

- You can set up container groups to order the sequence of the packing process, and create templates to support packing strategies.

- You can use scanners or other mobile devices to optimize precision in the picking and put-away processes.

Before going for the processes like Inbound, Outbound, Cycle Count etc, we first need to configure few set ups. These include-

- Storage Dimension Group Set up

- Tracking Dimension Group set up

- Warehouse Set up.

- Reservation Hierarchy.

- Item Set up.

- Location Type

- Location Formats

- Location Profiles

- Location Set Up Wizard

Let’s discuss each of them in details. So in this post I will discuss about the set ups that are needed to start any WMS processes.

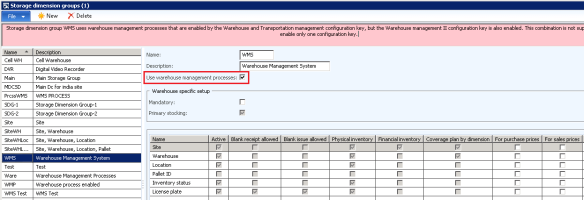

Storage Dimension Group Set Up

Storage Dimension groups help the way to control items that are stored and taken from inventory. These include extra of-

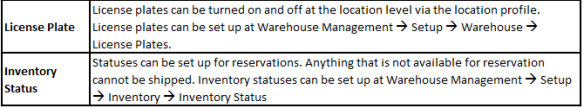

- Use Warehouse Management Process.

- Inventory Status

- License Plate

Navigate to : Product Information Management > Setup > Dimension Groups > Storage Dimension Group

Note: When “Use Warehouse Management Process” parameter is selected, it enables Inventory Status and License plate.

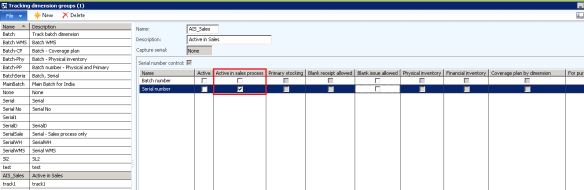

Tracking Dimension Group Set up

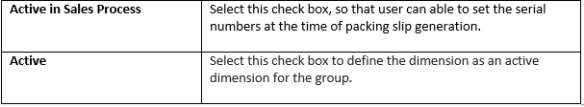

Tracking Dimension groups help the way to track the items that are stored and taken from inventory. These include extra of-

- Active in Sales Process

Navigate to:Product Information Management > Setup > Dimension Groups > Tracking Dimension Group

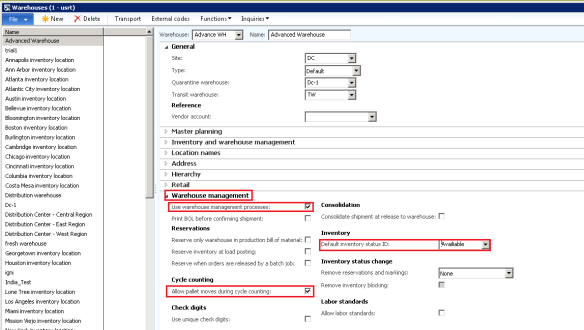

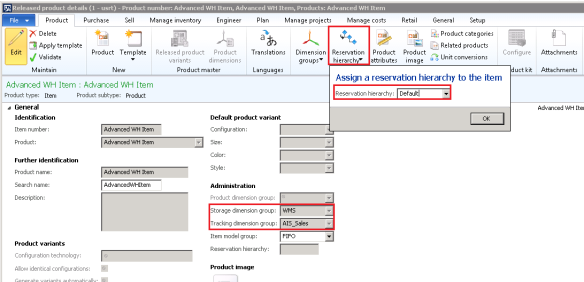

Warehouse Set Up

In order to use warehouse management,you need to create a warehouse and enable the warehouse management process.

Navigate to: Warehouse Management > Set up > Warehouse Set up > Warehouses

Under the Warehouse Management fast tab check the “Use Warehouse Management Process” check box. This will make the warehouse as the advanced warehouse.

NOTE: You needs to check this check box first and then need to save the record.

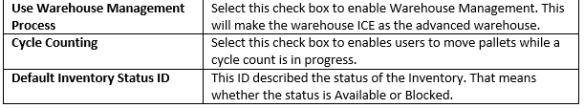

Reservation Hierarchy

A reservation hierarchy is used to defer reservation details beyond the point in the ordering process where you enter the order. For example > When goods are sold, inventory must be reserved to fill the orders. This reservation process will follow the rules of your reservation hierarchy.

Navigate To: Warehouse Management > Setup > Inventory > Reservation hierarchy

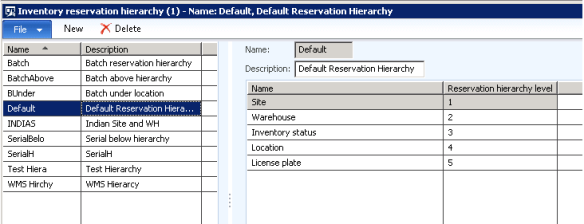

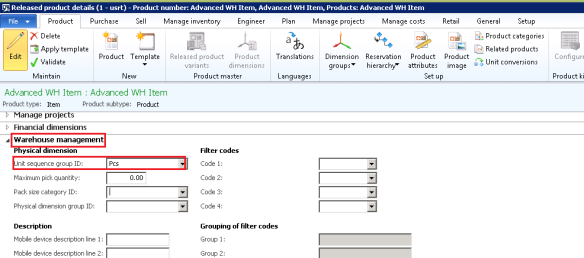

Item Set Up

Item creation is same as you used to do in AX 2012 R2. Attaching the Storage Dimension Group, Tracking Dimension group and Reservation Hierarchy (that we have created now) will make the item as Advanced Warehouse item.

Once these have been attached, next go to the Warehouse Management fast tab and enter a unit sequence group ID.

Note: The unit sequence group defines the sequence of units that can be used in warehouse operations. The sequence determines the order of units in which warehouse work is generated and it is applied when work is created for quantities on a purchase order line or transfer order line.

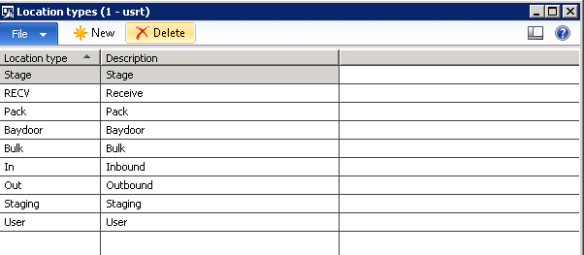

Location Type

Location types are used to describe or define the locations that the warehouse will be using.

Navigate to: Warehouse Management > Set up > Warehouse Set up > Location Types.

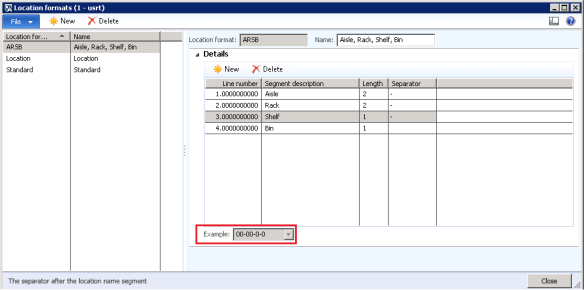

Location Formats

Location formats leads the users to define what the numbering system for the warehouse will be. These can have a unique format, depending on whether the user uses Aisles, Racks, Bins, Shelf, or whatever the structure resembles.

Navigate to: Warehouse Management > Set up > Warehouse Set up > Location Formats.

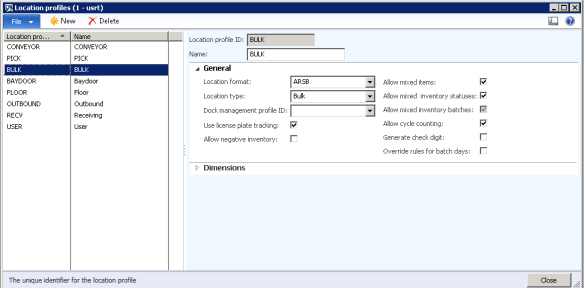

Location Profiles

Location Profile lets the user to specify whether a particular warehouse location is license plate controlled, whether it can be cycle counted, and whether it allows for mixing of inventory batches.

- Select Use license plate tracking.

- Select Allow mixed items.

- Select Allow mixed inventory status

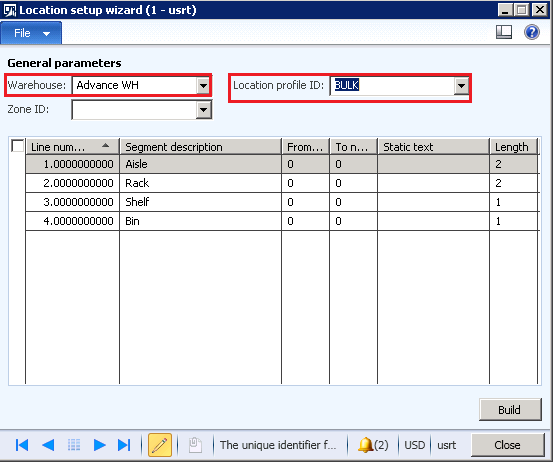

Location Set Up Wizard

The Location Setup wizard lets you create locations based on the formats that were previously defined. The process of creating the locations is simple

Navigate to: Warehouse Management > Set up > Warehouse Set up > Location Set Up Wizard.

- Select the respective Warehouse for which you want to create the locations.

- Select the Location Profile ID i.e. BULK or PICK

- Select the format of the Location.

- Once done click Build.

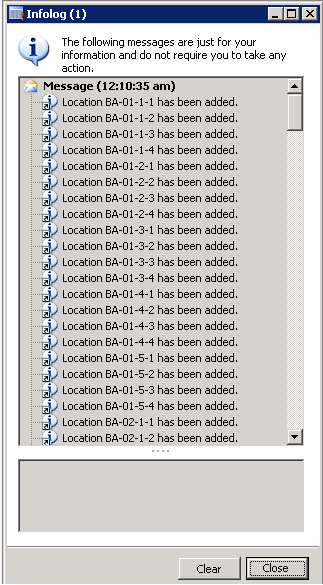

System will create all the Location names by permutation and combination.

In this similar way, other locations like PICK, CONVEYOR, BAYDOOR, USER and RECV needs to be Build.

This is the basic steps for the WMS processing. Without these steps we can’t move forward for any processes like Inbound, Outbound. In my next post I will start discussing about the Inbound, Outbound processes. I believe that this post must be helpful for those who have started the WMS feature. Till then keep DAXing 🙂 🙂

Pingback: Warehouse Management System- Inbound Process | Parashar's Blog On AX

Hi,

can you please help me with the advance warehouse process. I am doing site warehouse location and pallet setup in storage dimension group. I have done Purchase order for one item and done the receipt on inbound location. I have done PO invoice also.

Now I want to make a sales order for the same item. During picking list registration I am getting error that inventory cannot be picked because 0 is available from inventory. Sales order is looking that item on outbound location where as that item is still lying in inbound warehouse.

So I want to know how I can shift item from inbound location to outbound location so that I can process sales order.

Also if you can help me understand Inbound location, outbound location, Bulk location, Picking location and receipt location. what all this mean and what is the relation between these location and where and how these location will be used in inventory process.

thanks in advance…

Abhijeet Khedkar

within warehouse you can use Create movement work on Locations Form in warehouse management. and if two different warehouses you can use transfer order.